Universal Live Loading Disc Spring

- Brand: AIGI ENVIRONMENTAL INC

- Type: AIGI LIVE Loading Disc Spring

Compensate for gasket

Sealing load loss caused by bolt relaxation, high temperature metal fatigue and gasket creep

Compensate for gasket

Sealing load loss caused by bolt relaxation, high temperature metal fatigue and gasket creep

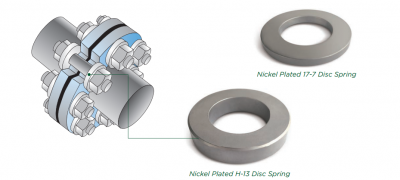

Disc Springs for Chemical Environments

➤ Nickel Plated H-13 Disc Springs & Nickel Plated 17-7 Disc Springs

The advanced Nickel Plated Technology gives AIGI NIF Disc Springs a high wear and corrosion resistant surface.

The special coating protects the spring metal surfaces from scratching and provides protection from acidic and alkaline corrosion during working application. The highly protected surface can even withstand prolonged exposure to halogens.

This tremendous corrosion resistance dramatically extends the disc spring life and greatly enhances its preload ability.

| Disc Spring Material | Yield Strength (psi) | Elastic Modulus (psi) | Temperature (∘C) | Surface Treatment |

| H-13 NiF Disc Spring | 220,000 | 30,000,000 | -156 – 600 | Nikel Plated |

| I7-7 NiF Disc Spring | 180,000 | 29,000,000 | -200 – 330 |

Nickel Plated H-13 Disc Springs Selection

| Size | Flat Load (N ±10%) |

Flat Torque (N$\cdot$m ±10%) (Light lubrication)

|

Size | Flat Load (N ±10%) |

Flat Torque (N$\cdot$m ±10%) (Light lubrication)

|

|

| M10 | 21587 | 43 | M40 | 469318 | 3755 | |

| M12 | 31467 | 76 | M41 (1 5/8″) | 475626 | 3927 | |

| M12.7 (1/2″) | 37870 | 96 | M42 | 476220 | 4000 | |

| M14 | 43180 | 121 | M45 (1 3/4″) | 540548 | 4865 | |

| M16 (5/8″) | 60588 | 192 | M48 (1 7/8″) | 541142 | 5195 | |

| M18 | 83164 | 299 | M50.8 (2″) | 586795 | 5963 | |

| M19 (3/4″) | 88294 | 336 | M52 | 753153 | 7833 | |

| M20 | 93577 | 374 | M56 (2 1/4″) | 757179 | 8480 | |

| M22 | 123324 | 543 | M58 | 842227 | 9770 | |

| M22.2 (7/8″) | 123376 | 549 | M64 (2 1/2″) | 940761 | 11949 | |

| M24 | 133718 | 642 | M70 (2 3/4″) | 1145108 | 15999 | |

| M25.4 (1″) | 162252 | 824 | M72 | 1421813 | 20474 | |

| M27 | 175735 | 949 | M76 (3″) | 1431187 | 21754 | |

| M28.5 (1 1/8″) | 208791 | 1193 | M80 | 1768216 | 28291 | |

| M30 | 214717 | 1288 | M82 (3 1/4″) | 1852016 | 30577 | |

| M32 (1 1/4″) | 266154 | 1703 | M85 | 2092327 | 35570 | |

| M33 | 266836 | 1761 | M88.9 (3 1/2″) | 2139667 | 38048 | |

| M35 (1 3/8″) | 314204 | 2195 | M90 | 2214563 | 39862 | |

| M36 | 314281 | 2263 | M95 (3 3/4″) | 2456390 | 46801 | |

| M38 (1 1/2″) | 397522 | 3030 | M100 (4″) | 2844483 | 57808 | |

| M39 | 397815 | 3103 | M105 | 2933132 | 61596 |

(1inch = 25.4mm 1lbs = 4.45N 1N =0.2248 lbs 1ft – lbs = 1.356Nm 1Nm=0.7375 ft-lbs)

➤ Remarks: NIF H-13 disc spring is compatible with bolts at 8.8grade/80D/SAE8.

* Conventional H-13 disc springs are available too.

Please consult with AIGI Environmental Inc. for all your standard and non-standard requiremnts.

Nickel Plated 17-7 Disc Springs Selection

| Size | Flat Load (N ±10%) |

Flat Torque (N$\cdot$m ±10%) (Light lubrication)

|

Size | Flat Load (N ±10%) |

Flat Torque (N$\cdot$m ±10%) (Light lubrication)

|

|

| M6 | 3236 | 4 | M33 | 67269 | 444 | |

| M8 | 4207 | 7 | M35 (1 3/8″) | 110142 | 769 | |

| M9.5 (3/8″) | 12308 | 23 | M36 | 113939 | 820 | |

| M10 | 12407 | 25 | M38 (1 1/2″) | 115840 | 883 | |

| M11 (7/16″) | 12439 | 28 | M39 | 118136 | 921 | |

| M12 | 15447 | 37 | M41 (1 5/8″) | 120142 | 992 | |

| M12.7 (1/2″) | 15536 | 39 | M42 | 122435 | 1028 | |

| M14 | 16096 | 45 | M44.4 (1 3/4″) | 137172 | 1219 | |

| M16 (5/8″) | 23977 | 77 | M45 | 137223 | 1235 | |

| M18 | 33282 | 120 | M47.6 (1 7/8″) | 146332 | 1394 | |

| M19 (3/4″) | 35781 | 136 | M48 | 172148 | 1653 | |

| M20 | 41398 | 166 | M50.8 (2″) | 178093 | 1809 | |

| M22 (7/8″) | 42472 | 187 | M52 | 179663 | 1868 | |

| M24 | 42873 | 206 | M56 (2 1/4″) | 227491 | 2548 | |

| M25.4 (1″) | 43503 | 221 | M63.5 (2 1/2″) | 273982 | 3480 | |

| M27 | 43657 | 236 | M64 | 274499 | 3514 | |

| M28.5 (1 1/8″) | 65168 | 372 | M70 (2 3/4″) | 332006 | 4638 | |

| M30 | 65252 | 392 | M72 | 382624 | 5510 | |

| M32 (1 1/4″) | 65429 | 419 | M76 | 391897 | 5957 |

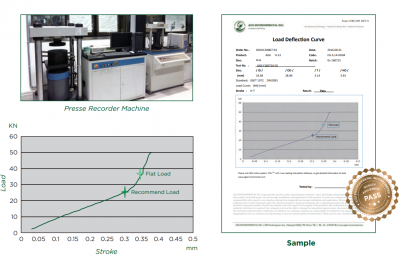

Quality Assurance

A Load Deflection Curve: Certified.

We takes great pride in our highest quality standards of products.

To assure all the disc springs 100% acceptable, our quality assurance and testing facilities can provide a Load Deflection Curve for each batch of orders.

A Load Deflection Curve from AIGI, is a unique service that you could not find everywhere.

We have sold over 5,000,000 disc springs in the last 10 years and sealed over 1,600,000 controls.

Updating………..