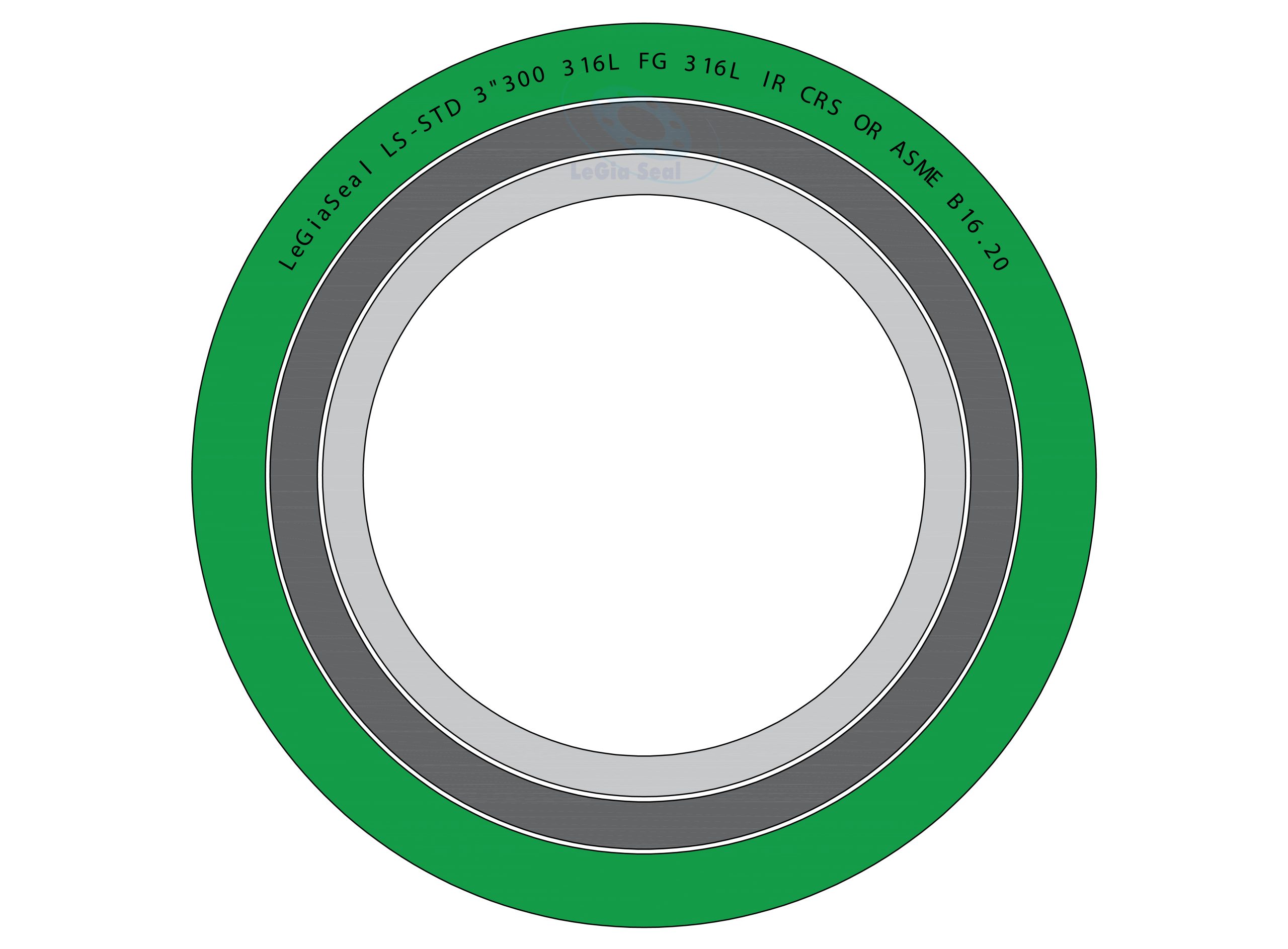

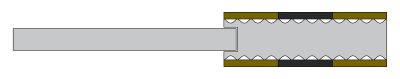

Spiral wound gasket Standard (LS_STD)

- Brand: Legiaseal

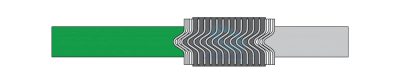

- Type: Semi-Metallic Gasket Spiral Wound Gasket Standard

With widely usage, it is applicable to sealing under heavily alternating temperature or pressure such as the static sealing at flanges of pipeline, valves, pumps, heat exchangers, columns, manhole and hand hole. It has a wide application in petrochemical mechanical, electric power, metallurgical, ship-building, pharmaceu-tical, nuclear power and aerospace industries.

Applications:

- Petrochemical, refinery, power plant, offshore, and general industrial piping systems.