OVON Live Loading Disc Spring

- Brand: AIGI ENVIRONMENTAL INC

- Type: AIGI LIVE Loading Disc Spring

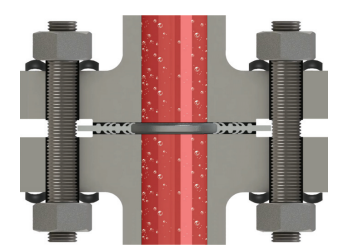

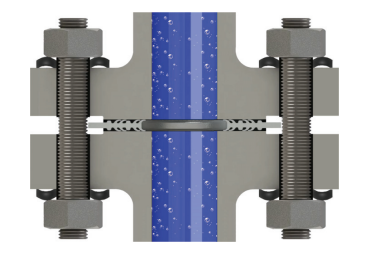

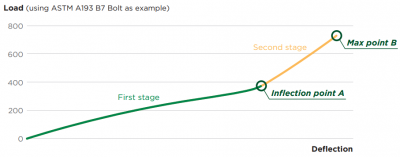

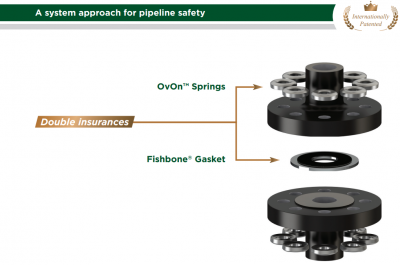

The new OvOn™ bidirectional spring not only acts as a normal spring to compensate for load loss but also acts in the opposite direction to prevent over-compression of the gasket.