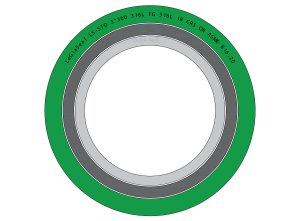

Metal Jacketed Gaskets, as the name suggests, consist of a metallic outer shell with either a metallic or non-metallic compressed fiber filler. The filler material gives the gasket resilience, while the metal jacket protects the filler and resists pressures, temperatures and corrosion. Metal jacketed gasket is specially designed and widely used for heat exchangers, autoclaves, columns, pressure vessels, flue stacks, boilers, gas mains, valve bonnets, pumps and similar services.

Suitable for narrow flanges, Good blow-out resistance, The metal jacket covering the filler material prevents contamina-tion, Suitable for high temperatures, Ensures high elasticity and recovery, Nearly any dimension and shape can be mode, Economical &.perfect sealing stability, Easy to handle and install.

Materials:

- Jacket: 304(L), 316(L), 321, carbon steel, copper.

- Filler: Graphite, PTFE, Non- asbestos C.fiber, Ceramic.

Service temperature:

- Carbon steel: 300 °C

- copper: 400 °C

- stainless steel: 530 °C

- Max Pressure (bar): 64 bar

ASME B16.20/ for B16.5 Flanges, B16.47 Series A Flanges, B16.47 Series B Flanges,

Schedule of Standard Shapes For Heat Exchanger Gaskets, Other bar configurations available on request

Mill test report, Asbestos free test report-SGS