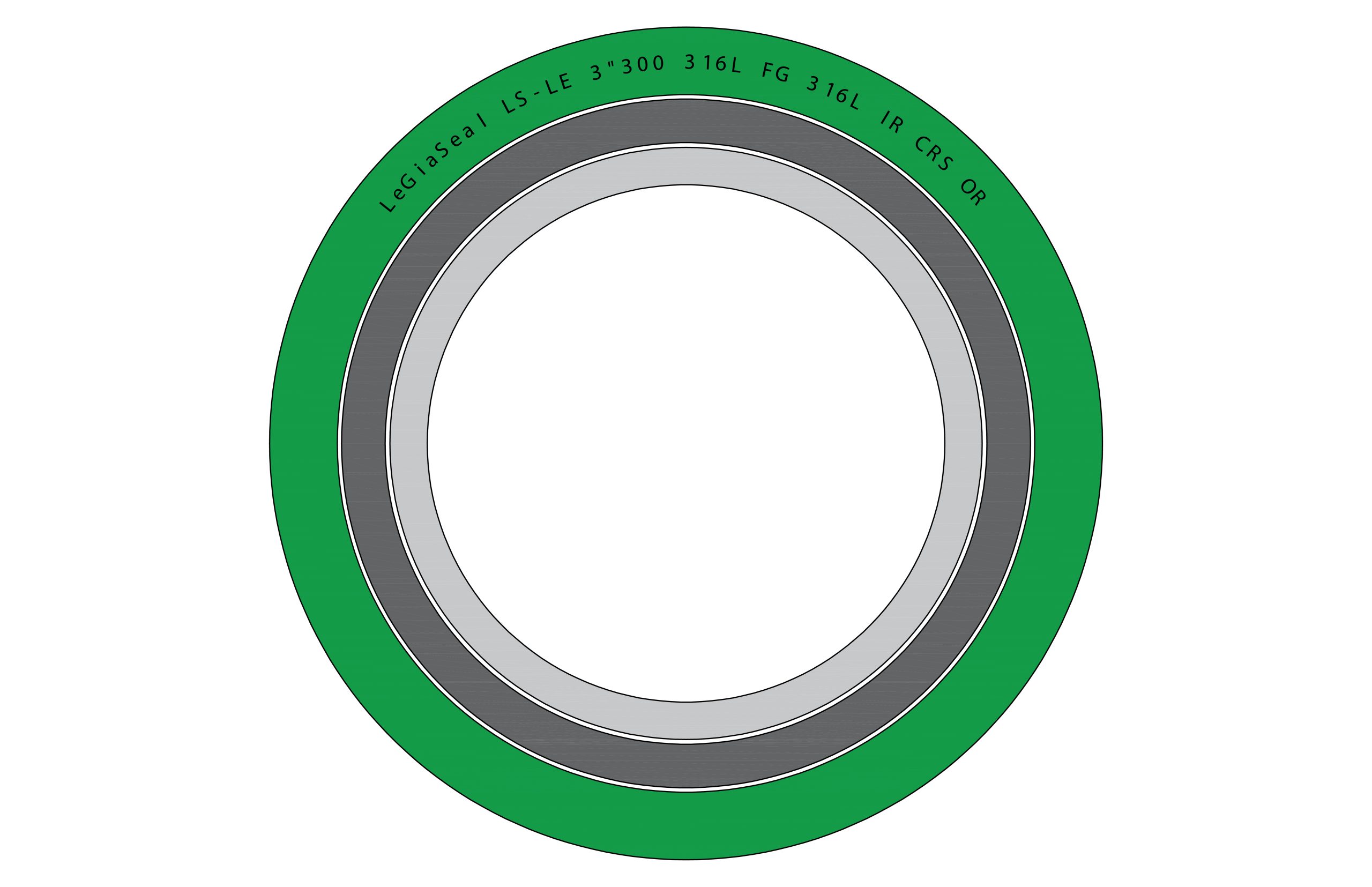

The LS_LE style gasket is the ideal choice when high density and low emissions are critical. This enhanced spiral wound design includes essential components such as a carbon steel guide ring and a stainless steel inner ring.

For low-emission performance, the manufacturing process carefully controls the number of metal wire wraps per inch. A higher wrap count produces a denser, stronger gasket, effectively reducing emissions. The machinery is set to higher pressure levels, creating increased tension on the winding to compact the filler and extrude it at least 0.008” (0.2032 mm) above the metal surface. This extruded layer forms a thin barrier between the winding and the flange surface, filling minor imperfections and ensuring a superior seal.

This advanced design is suitable for flanges in the Class 150 to 2500 range, providing reliable sealing performance and minimized emissions.